Chain drive and synchronous belt wheel what advantages and disadvantages?

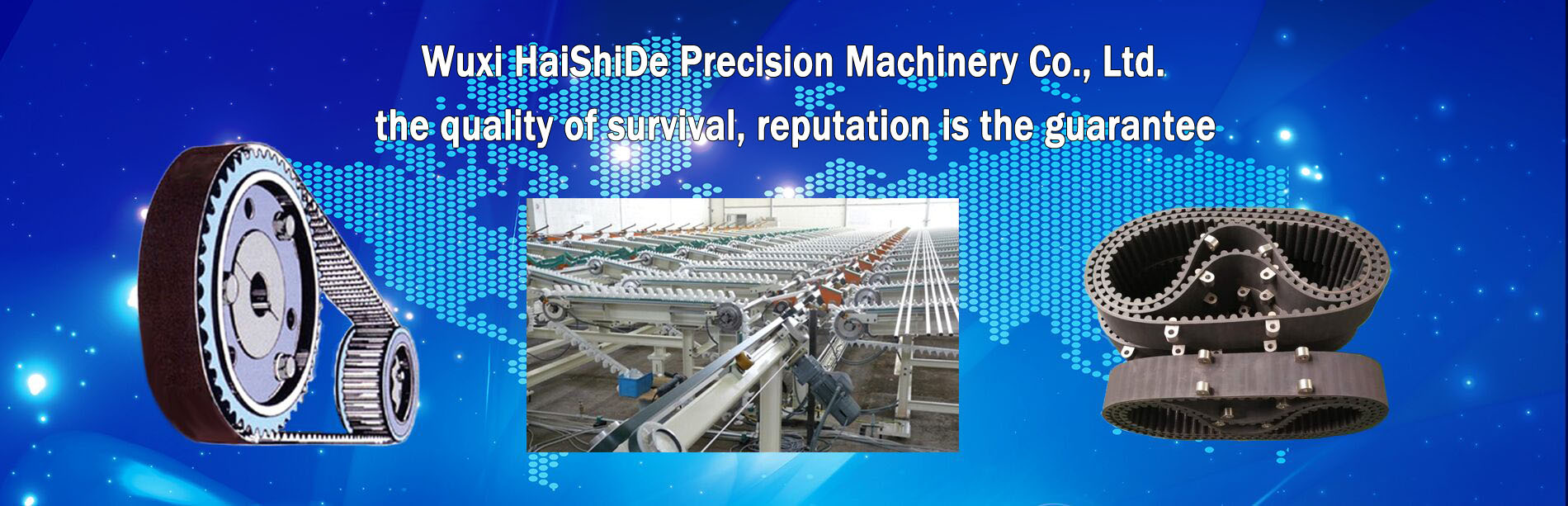

Synchronous belt transmission characteristics and application of synchronous belt drive is normally provided by the driving wheel and the driven wheel, and a belt wheel. Principle of work: the use of flexible member (band),intermediate (or mesh) by friction transmission of rotary motion and power in the main, driven shaft. Composition: it is composed of the synchronous belt (belt) is made of steel wire tensile body, outsourcing polyurethane orrubber. Characteristic: cross section is rectangular, circular belt equidistant horizontal tooth belt, synchronous beltwheels also made the appropriate profile. Transmission characteristics: by synchronous belt tooth andsynchronous belt transmission gear between the two, no relative sliding, and the circumferential speed synchronization, it is called synchronous belt transmission. Advantages: 1 constant transmission ratio compact structure; 2; 3 with thin and light, high tensile strength, so the speed of up to 40 m/s, the transmission ratio can reach 10, the transmission power of up to 200 KW; 4 high efficiency, up to 0.98. Characteristics and application of chain drive sprocket, chain ring: role: the engagement between the chain and sprocket to drive between real bythe parallel axis. Features: compared with belt drive sprocket drive no 1 elastic sliding and skidding, to maintain accurate than the average transmission; 2 required tensioning force is small, the pressure acting on the shaft of the small, can reduce the friction loss of bearings; the 3 compact structure; the 4 can be in high temperature, oiland other harsh environments than work; and the transmission gear is lower 5 manufacturing and installation accuracy, center distance is larger the transmission structure is simple; disadvantages: instantaneous speed and instantaneous transmission ratio is not a constant, the unstable transmission, have a certain impact and noise.Application: it is widely used in mining machinery, agricultural machinery, petroleum machinery, machine tools andmotorcycle. Scope of work: the transmission ratio: I = 8; a < 5~6 center distance: m; power transmission: P = 100 KW v = 15; peripheral speed: m/s: n = 0.95~0.98; transmission efficiency